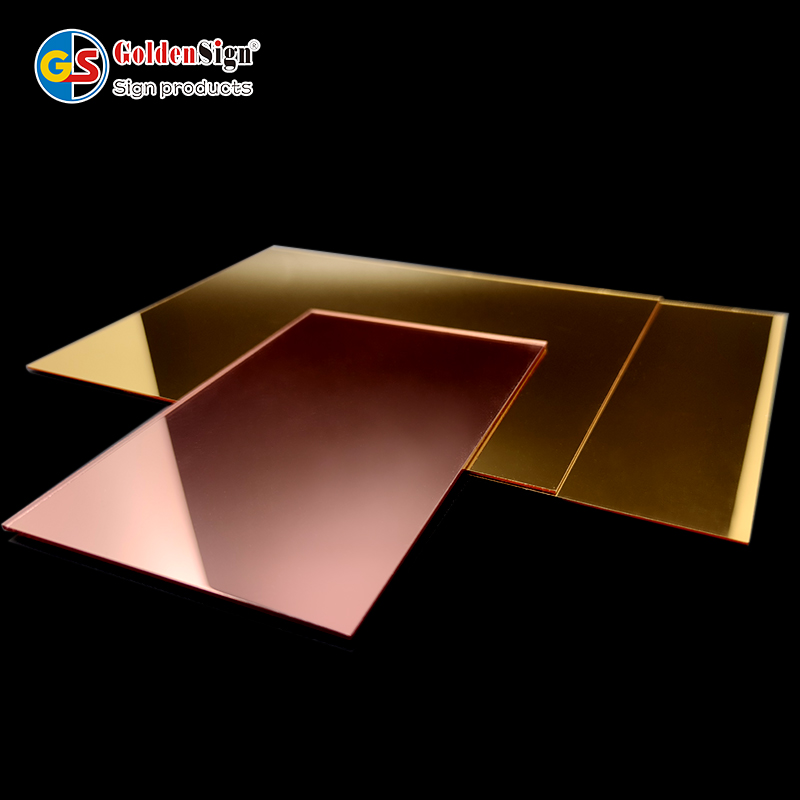

Goldensign Low Price solid acrylic sheet 4*8ft Mirror Acrylic Sheet large pmma sheet

Goldensign Low Price solid acrylic sheet 4*8ft Mirror Acrylic Sheet large pmma sheet

·Density: 1.2g/cm

·Color:Transparent/clear, colored for choose

·Packing: Per sheet: Both sides covered with kraft paper to protect surface

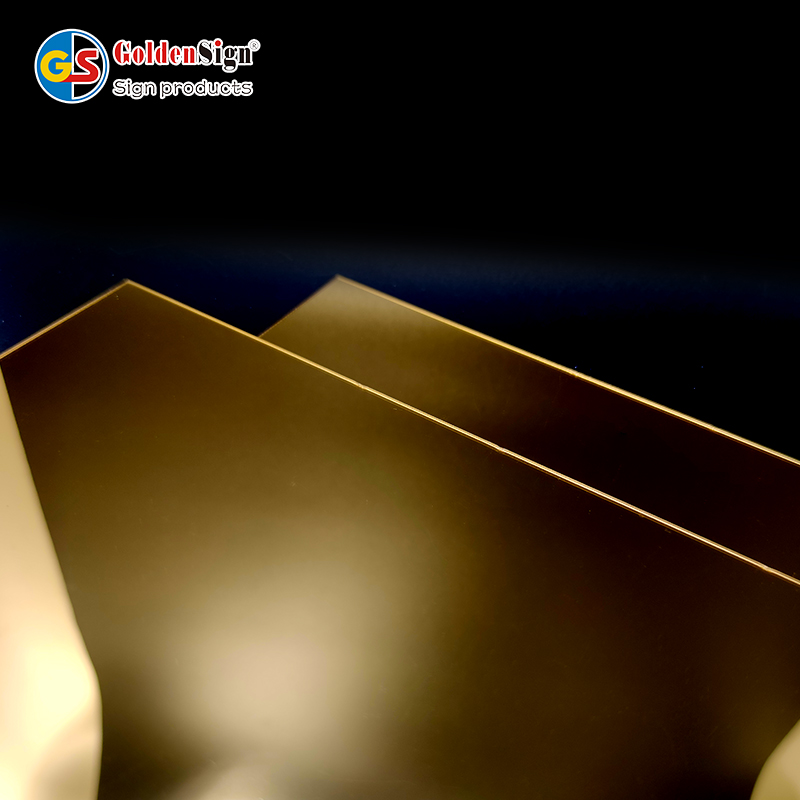

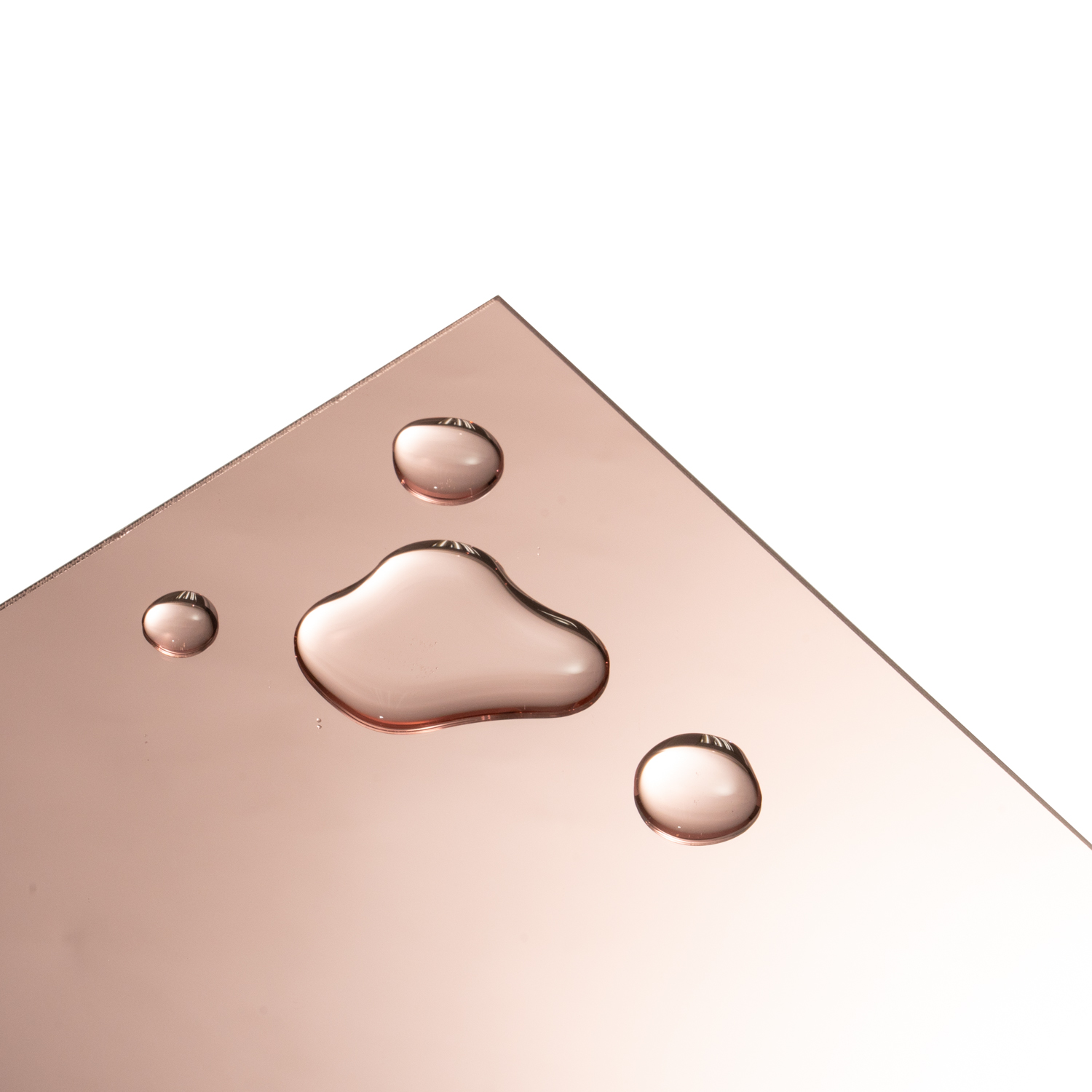

·Surface: High hardness and glossy

Goldensign Low Price solid acrylic sheet 4*8ft Mirror Acrylic Sheet large pmma sheet

The base material of mirror acrylic board is PMMA. It is easy to process and make, and has good plasticity. It can be processed by spraying, bending, cutting, etc. to make mirror boards of different shapes

and sizes. It is often used in commercial design. , such as display cabinets and showcases in shopping malls. At the same time, it has high toughness and is not easy to break, which makes it safer and more reliable in home decoration, especially suitable for families with children.

| Width*Length(mm) | Thickness(mm) | Density | Color |

| 1250*1850,1250*2450,1050*2050,2050*3050 etc... | 1-200 | 1.2 | As requirement |

In order to offer a good price, we need your kindly help to confirm us about the following details as the reference

1. Color (transparent, semitransparent, white, black, red, blue, green and as per customer's requirement)

2. Thickness (2mm~30mm)

3. Size (1220x2440mm standard)

4. Quantity to check the delivery time

|

|

|

| Types | Items | Units | Value | Test method |

Mechanical Characteristics | Elasticity Modulus | kg/cm2 | 28000 | ASTM D-638 |

| Curving Intensity | kg/cm2 | 1260 | ASTM D-790 | |

| The Curving elasiticity rate | kg/cm2 | 28000-35000 | ASTM D-790 | |

| Compressing Intensity | kg/cm2 | 1260 | ASTM D-695 | |

| Lzod(Notched) | kg/cm2 | 0.4 | ASTM D-256 | |

| Rockwell Hardness | ft-lbs/in | M-100 | ASTM D-785 | |

Heat Characteristics | Moulding temperature | ℃ | 150 | |

| Transfigurating temperature | ℃ | 100 | ASTM D-648 | |

| Intenerating point | ℃ | 112 | ASTM D-1525 | |

| Line expanding modulus | cm/cm/℃ | 54*10-6 | ASTM D-696 | |

| Self extinguishing temperature | cm/cm/℃ | 64*10-6 | Cenco-Fitch | |

| Specific heat | ℃ | 4436 | ASTM D-1929 | |

| Flection rate | ℃ | 0.35 | (BTU/lboF) | |

Optical Characteristics | Flection rate | 1.49 | ASTM D-542 | |

| Light transmission rate | % | 92 | ASTM D-1003 | |

Others | Water absorbing rate | 24hrs | 0.3 | |

| Smell | none | |||

| Gout | none |