Acrylic Sheet vs. Glass: Which One Truly Fits Your Project?

You're developing a display case.A signage system.A lightbox. A protective screen.And the same question keeps coming up:

“Glass or acrylic?”Glass — familiar, classic, optically clear.But is it truly the optimal choice for real-world, high-demand applications?

Let’s go beyond surface comparisons.

Let’s evaluate what matters most:Cost. Safety. Logistics. Fabrication.

This is not just a material comparison —

It's a comparison of outcomes.

Why Are More Commercial Projects Choosing Acrylic First?

Not because it looks high-tech.But because it performs — consistently and efficiently.

Clear acrylic weighs approximately 50% less than glass.Not just lighter — significantly lighter.

A single sheet? You may not notice.But scale that to pallet loads or full builds, and the difference is dramatic.

Lower freight costs

Simplfied handling

Quicker installation

Especilly in projects like large-format signage, retail partitions, or trade show booths,

lighter material equals higher operational efficiency

Breakage Risk: What’s the Real Cost When Things Go Wrong?

Glass delivers a sleek look — until it cracks.

Damaged during transit?

Chipped while mounting?

Dropped during use?

Every incident introduces delays, replacements, and frustration.

Acrylic offers exceptional impact resistance —

Up to 10 times more durable than glass at the same thickness.

This isn’t marketing fluff. It’s quantifiable reliability.

Visual Performance: Does Glass Still Have the Edge?

Not anymore.

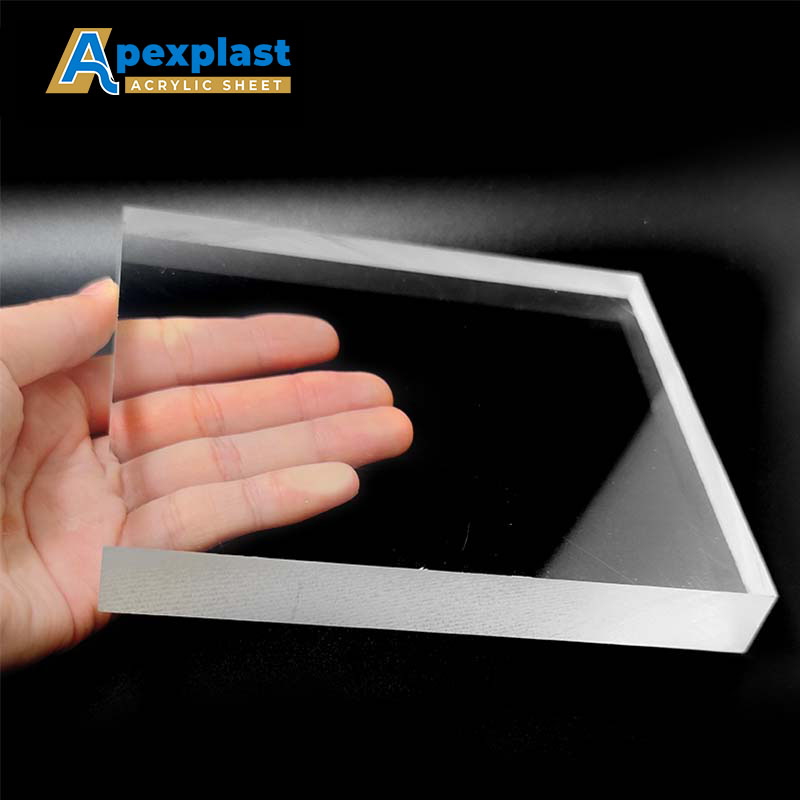

Premium-grade acrylic sheets offer 93%+ light transmittance,

matching — and in some cases surpassing — standard glass.

No green hue at the edges

No fading or discoloration over time

UV-stabilized options available for long-term clarity in outdoor or backlit use

Perfect for:

Backlit signage

Product showcases

Office partitions

Light diffusers and panels

Result: Exceptional clarity with enhanced longevity.

Cost Considerations: Beyond Just Sheet Price

On paper, glass may appear less expensive.

But the true cost involves more than just material:

Higher shipping and handling expenses

Increased risk of damage and returns

Specialized installation needs

Downtime from repairs or replacements

Acrylic streamlines every stage of the project:

Easier cutting

Faster processing

Safer installation

Less labor. Less waste. Less hassle.

That’s how acrylic delivers real bottom-line savings.

Versatility: Acrylic Isn’t Just a Substitute — It’s an Upgrade

Acrylic is not just a “glass alternative.”

It’s the better-fit solution for a wide range of B2B applications:

✅ Retail displays and point-of-purchase units

✅ Protective barriers and sneeze guards

✅ LED lightboxes and illuminated signs

✅ Equipment covers and industrial enclosures

Compatible with laser cutting, CNC routing, thermoforming, bonding —

It’s built for speed, scale, and flexibility.

So… What Are You Really Building? If the project is small-scale, with minimal handling, and fragility or weight isn't a concern — glass might suffice.

But if you're focused on:

Reducing freight and installation time

Avoiding breakage-related downtime

Increasing efficiency and safety

Managing total cost of ownership

Then acrylic isn’t just a smart option — it’s a strategic one.

Ready to choose the material that moves your business forward? contact us now~!