Acrylic Sheet vs PVC Sheet: Which One Fits Your Project Best?

Which is better, acrylic sheet or PVC sheet? The truth is, there isn’t a single winner. These two sheets are built differently, serve different purposes, and are both widely used — from advertising boards to construction projects. Knowing the differences will make your choice much easier.

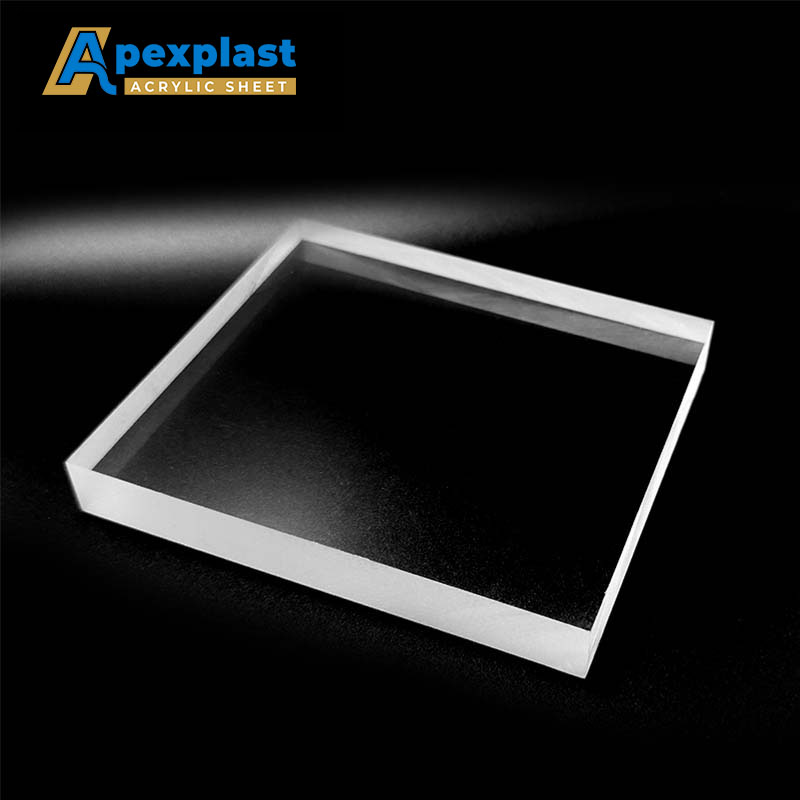

What Is Acrylic Sheet?

Acrylic sheet (PMMA, sometimes called “plastic crystal”) is known for one thing above all — clarity. High-grade acrylic can transmit up to 92% of light, nearly the same as optical glass.

That glass-like transparency, plus a glossy surface, good hardness, and strong weather resistance, makes acrylic a favorite for:

Display stands:Signage and light boxes;Lighting panels;Aquariums and decorative panel

Outdoors, acrylic can last for years without turning yellow or brittle. That’s why it’s often chosen for long-term, visible projects.

Another edge? It’s easy to work with. Acrylic can be cut, engraved, polished, thermoformed, even bent into curves — perfect for creative displays and custom designs.

What Is PVC Sheet?

PVC sheet (polyvinyl chloride) performs very differently. It’s not as clear as acrylic, but offers:

Better chemical resistance

Higher impact strength

Greater flame resistance

That’s why PVC shows up in:

Wall panels and cladding

Cabinets and furniture

Construction materials

Foamed PVC sheets (PVC foam board) are even lighter. They print well, so they’ve become a go-to for advertising boards, exhibition displays, and digital printing projects.

Acrylic vs PVC — Quick Comparisons

Transparency → Acrylic wins: glass-like clarity at 92%.

Weather resistance → Acrylic holds up better outdoors; PVC breaks down faster under UV.

Fire resistance → PVC wins: naturally more flame-retardant.

Impact strength → PVC stronger, acrylic may crack if hit hard.

Processing → Acrylic allows high-end finishes; PVC is easier to glue and screw.

Cost → PVC is more budget-friendly, especially for temporary or large-scale use.

So, Which One Should You Pick?

It depends on your needs:

Go with Acrylic Sheet if you want clarity, durability, and a premium look — signage, displays, lighting panels.

Choose PVC Sheet if you need a low-cost, durable, flame-resistant panel — construction, furniture, advertising boards.

Why Apexplast for Acrylic Sheets?

At Apexplast, we’ve been focused on one thing for over 21 years — making quality acrylic sheets. Our advantages:

Advanced casting and extrusion production lines

Consistent thickness, smooth surface

SGS-tested raw materials, safe and reliable

Wide range of colors, finishes, and custom sizes

Today, Apexplast supplies distributors and wholesalers in more than 90 countries. Factory-direct, consistent quality, competitive prices — that’s what keeps partners choosing us.

Looking for a trusted acrylic sheet manufacturer? With Apexplast, you won’t get lost.

If you are looking for a reliable PVC sheet manufacturer, we recommend Goldensign. Goldensign is a leading professional manufacturer of PVC foam board and PVC foam sheet in China. Visit our website: https://www.pvcfoamsheet.com/