Acrylic Sheet Packaging Guide | Professional Acrylic Sheet Factory Insights

When people talk about acrylic sheet, most of the attention goes to clarity, thickness, or surface finish. Packaging is often treated as an afterthought. Just wrap it, stack it, ship it out. In reality, packaging is where many problems begin—or where quality is protected all the way to the customer’s warehouse.

At Apexplast, as an acrylic sheet factory supplying different markets for years, we’ve learned one simple thing:

a good acrylic sheet is only as good as the way it’s packed.

Scratches, corner cracks, edge damage, moisture marks. These don’t usually happen during production. They happen during handling, transport, and unloading. That’s why acrylic sheet packaging deserves real attention, not shortcuts.

What Acrylic Sheet Packaging Needs to Protect Against

Acrylic sheet looks strong, but it has clear weaknesses.

Surface scratching

Edge and corner impact

Sheet-to-sheet friction

Long-distance vibration

Humidity and temperature change

A professional acrylic sheet factory doesn’t pack “by habit”. Packaging should respond to these risks, depending on sheet size, thickness, and shipping method.

At Apexplast, packaging is treated as part of production, not logistics.

Standard Acrylic Sheet Packaging Methods

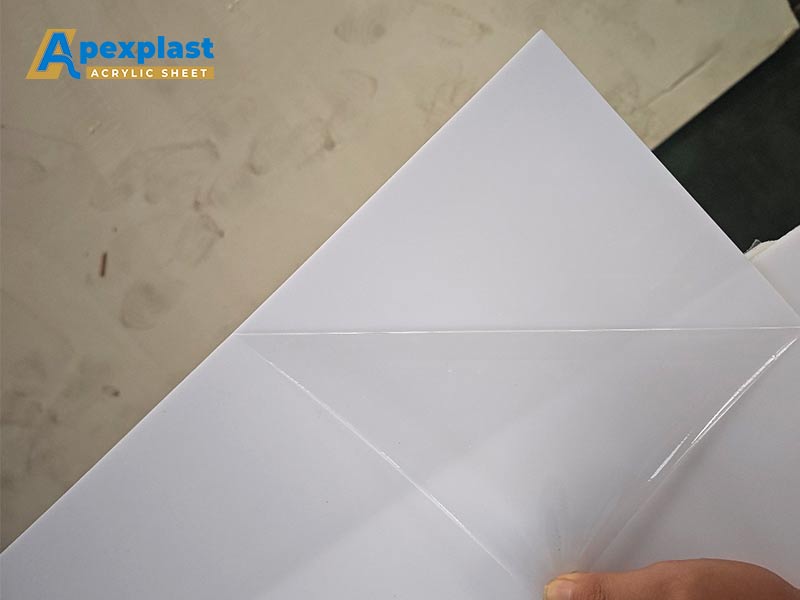

1. Protective Film on Both Sides

Every acrylic sheet leaving our factory keeps its protective film on. No exceptions.

This film:

Prevents surface scratches

Reduces static dust

Protects during cutting and installation

Some buyers ask to remove it. We usually recommend keeping it until final use. Especially for export orders.

2. PE Foam or Soft Paper Interlayers

When acrylic sheets are stacked directly, friction damage is almost guaranteed.

Apexplast uses:

PE foam sheets for high-clarity acrylic sheet

Soft kraft paper for standard packing

Extra corner protection for large formats

This small detail reduces complaint rates more than any inspection step.

3. Wooden Pallet Packing for Acrylic Sheet

For most export orders, pallet packing is essential.

A proper acrylic sheet pallet should:

Be flat, dry, and strong

Match sheet size to avoid overhang

Use strapping that holds, not crushes

As an experienced acrylic sheet factory, Apexplast customizes pallet size instead of forcing standard pallets. That avoids stress points during transport.

4. Wooden Crate Packing for Long-Distance Shipping

For thick acrylic sheet, oversized panels, or long sea routes, wooden crates are the safest option.

Crate packing is often used for:

15mm+ acrylic sheet

Large-format sheets

Mixed-size orders

Inside the crate:

Sheets are fully supported

Movement is restricted

Moisture protection is added when needed

Yes, it costs more. But it costs less than replacing damaged acrylic sheet after arrival.

Export Packaging: What an Acrylic Sheet Factory Must Consider

Shipping acrylic sheet internationally adds more variables.

Sea vs land vs air

Transit time

Climate differences

Multiple loading and unloading points

Acrylic sheet can expand and contract with temperature. Poor packaging locks the sheet too tightly or leaves it too loose. Both cause problems.

At Apexplast, we adjust packaging based on destination market. Middle East, Europe, South America. Different routes, different solutions. That’s factory experience, not guesswork.

Custom Packaging for Special Acrylic Sheet Orders

Not every order is standard.

Some customers need:

Small quantities, mixed sizes

Retail-ready packaging

Repacking for local distribution

Extra labeling or barcodes

A flexible acrylic sheet factory should be able to adapt. Apexplast offers customized packaging solutions because cooperation doesn’t end at production. It continues until the customer receives usable material.

Why Acrylic Sheet Packaging Reflects Factory Responsibility

Good packaging is invisible when it works. But when it fails, everything else becomes meaningless.

We believe this:

If an acrylic sheet arrives damaged, the factory is still responsible. Even if the sheet was perfect when it left the line.

That mindset shapes how Apexplast works. We don’t pack to meet minimum requirements. We pack to reduce risk. For our clients, and for ourselves.

Choosing the Right Acrylic Sheet Factory Means Fewer Problems Later

Many packaging issues are not “shipping problems”. They are factory decisions.

Thin protection to save cost

Standard pallets for all sizes

No testing for long routes

A reliable acrylic sheet factory plans ahead. That’s what allows customers to focus on their business, not claims and delays.

At Apexplast, packaging is part of trust. Quiet, solid, and reliable.

Let’s Talk About Your Acrylic Sheet Packaging Needs

If you’re sourcing acrylic sheet and care about how it arrives—not just how it looks on paper—we’re open to talk.

Tell us:

Sheet size and thickness

Destination

Handling conditions

We’ll recommend a packaging solution that makes sense, not one-size-fits-all.

Contact Apexplast today.

Let’s protect quality all the way, and build long-term cooperation.